Here, I'm using the mill to cut a stopped groove on the back of the lower middle rail:

A while afterwards all four middle rails are (mostly) complete:

These are done save for the mortises for the floating tenons on the lattices themselves, the fitting of which is a step also waiting to be completed.

Another view:

The lower rails have tall inner faces because they serve as side running surfaces for the lower runners on the drawers.

All the rails have a mitered lip at the exposed front faces:

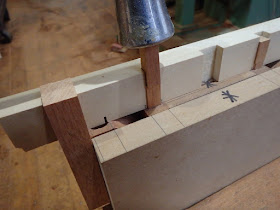

With the mill back up and running, I could also resume work on the floating tenons installation on the lattice assemblies. I used the mill to accurately make up a fixture which allows for precise spacing and fixturing of the floating tenons:

Here, I'm checking everything looks right, and I didn't make a mathematical error with the jig notching, relative to the connection points on the end of the lattice, sandwiched as it is at present in another fixture:

The positioning jig is then trimmed on the table saw, and end stops are fitted so a look-see can be done with the floating tenons which fit into the ends of the horizontal lattice bars:

A drift is used to set the tenons all the way down in their mortises:

Glued up, and one step closer:

All for this round - thanks for your visit!

No comments:

Post a Comment

All comments are moderated. Spamming and comments containing links unrelated to blog content will be deleted.