I mentioned three common approaches to drawer construction, the nailed bottom, the dadoed floor, and the drawer slip methods, and discussed their various merits and defects. A commenter reminded me of another system used on drawers, which I consider a variant of the drawer slip: the Swedish invention of NK drawer construction. Articles on this drawer construction method have appeared in Fine Woodworking magazine, in issue #9 and issue #150. I have neither issue on my shelf, but have at some point in the past read those articles and I'm sure a certain piece of that memory remains, and it likely influences my current drawer design ideas.

The NK method involves glueing a runner, often L-shaped, onto the bottom edge of the drawer side, and thereby holding the drawer side wall off of the cabinet interior. This addresses one of the defects common to all drawer construction methods which place the drawer sides right against the interior of the cabinet: there is a large scraping surface, which adds noise and friction to drawer operation. If the drawer sides were to swell in thickness, or bow outward from seasonal movement or stresses released from when the drawer was glued up and perhaps over-clamped, then the friction between the sides and the cabinet interior only gets worse, and the drawer may bind quite tightly at certain times of the year, especially if originally installed with the coveted 'piston fit'.

Here's a view of an NK drawer - actually this but one type of NK drawer, the kind which employs plywood bottom panels:

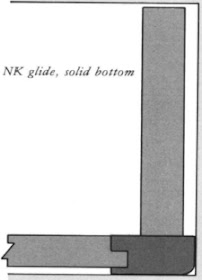

The other form of NK drawer, the rarer beast, similarly uses a runner to broaden the contact zone however the bottom panel is solid wood and that panel does not lap underneath the drawer side as in the plywood version:

Not much meat left on the bottom of the dado in that picture! Notice with both NK types that the side of the drawer is kept back from the runner's outer edge by 1/16" or more, which solves the drawer side friction issue quite nicely. These are still glued-up constructions, and if glue were to be the primary means by which I was to put drawers together, I think NK would be an excellent choice. Another advantage of NK, which alludes to a point made by Dennis Young in the previous post in regards to dovetailed drawers, is that the wide runners, by virtue of the fact that they are glued across the corner of the drawer carcase, stiffen the drawer against racking.

Though I didn't have NK in mind when I designed the drawers for this mizuya, by virtue of their glued construction and use of plywood (in the typical version you will see) they would be largely ruled out anyhow. That said, in reviewing the articles on the NK construction method I can say that what I came up with I can draw some points of similarity to be sure. Perhaps I was 'influenced' by NK or simply 'under the influence' when I came up with this design. You be the judge.

So, here's the drawer construction I have developed, in exploded view:

As you can see, there are rather more parts to this drawer than most other drawers you will come across - 8 principal parts, and 16 assorted keys and wedges.

Another view:

As you might expect, there is a special assembly sequence, however, since no glue is involved, this should be a stress-free affair.

First step is to slide the dovetail-tenoned, sliding dovetailed stiffening batten into the dado on the underside of the floor panel:

The dovetailed batten to reinforce thin panels is a standard of Chinese classical furniture construction. The sliding dovetail can be tricky to assemble, however the thin panel can be flexed to open the dovetail slot, greatly facilitating assembly. I don't even need to taper the sliding dovetail. The floor panel grain runs crosswise to the drawer's depth, as is -uh, was - standard in western drawer making. I guess the standard now is plywood.

Next, the drawer sides assemble to the slides. The slides are ideally a hard-wearing and preferably oily, self-lubricating type of wood - the absolutely perfect and ideal material here is lignum vitae, and I happen to have an adequate amount of stock in that very species. I was wondering what I was going to do with it!

The connection between slide and side panel might be done with sliding dovetail, however I was apprehensive about this connection due to assembly sometimes being a problem with long sliding dovetails and the narrow neck of the dovetail presenting a zone of weakness, given the drawer sides which are just 3/8" thick. So instead I designed a sliding hammerhead joint, which I think will be plenty strong:

You can see how my construction method draws upon the drawer slip/NK methods, except I am wrapping right around three sides of the the drawer side member instead of one or two. Like NK, I am keeping the drawer sides away from direct contact with the cabinet interior partitions. As the side panels are slim, and the offset not too much from the outer edge of the slide, the interior room lost by moving the side panels in is not excessive, as you get when using metal slides.

I will need to obtain a custom router bit to cut this sliding hammerhead joint, or fabricate a plane to do it. The slide itself is slid on until it is about an inch or so shy of full connection. You'll see why soon enough.

Next step is to assemble the side to the rear drawer panel, which connects to the side panels with double-wedged multiple mortise and tenons:

Once both sides are assembled to the rear panel and floor, the drawer front can be brought into position from below:

The drawer front assembles to the drawer sides using sliding dovetails. Sliding dovetails can cause problems in assembly, as I've noted above, so instead of a single long sliding connection, I have made the dovetail mortise stepped at about the 1/3rd depth mark:

Since the drawer front is thick and its dovetail mortise cannot be flexed open, I need to make the dovetail mortise and tenon with a slight taper. The drawer side's dovetail male tenon is not stepped.

The drawer front slides up to assemble:

Now the reason why the slides were held back becomes apparent - the assembly of slides and floor now can be slid forward until the floor's leading edge, which has a tongue cut in it, inserts into a corresponding dado in the drawer front. The slide, I will add, has a small stub tenon on the front which also inserts into the drawer front's dado:

Finally, a pair of parallelogram-shaped keys are driven down to complete the front sliding dovetail connections on the drawer front:

Detail:

The parallelogram-shaped pins should be removable for drawer repair to occur, and I'm considering having the pins protrude a tiny bit more into the drawer interior to facilitate their removal should it become necessary.

On the underside of the box, a pair of wedging pins are driven in to lock the dovetail batten's dovetail tenons to the slides:

This batten also serves as a tie, which helps restrain any potential for the drawer sides to bow outward. The drawer sides also have elongated cut outs in that middle zone to allow the floor batten tenons to insert and to allow the complete assembly of floor and slides to be slid forward to join to the front panel.

A view of the drawer from behind, all assembled:

The lignum vitae slides will run in corresponding lignum vitae runners inside of the cabinet, which, as far as I am concerned, means they should virtually never wear out, even if the cabinet and its drawers were to be operated underwater near geothermal vents for extended periods :^)

So there we have it, naked and shining, out for the world to see. I acknowledge that a principal drawback of the system I have drawn is its relative complexity compared to other drawer construction systems. Relative to the rest of the cabinet however, the drawer are not especially complicated. This drawer construction will also be laborious to construct and will require exacting joinery fits to be successful, so that virtually guarantees it will not become any sort of widely used construction technique. That said, the joinery, while a little fussy perhaps, is actually straight forward, mortise and tenon, dovetails - bread and butter stuff for anyone used to cutting joinery. I look forward to making these drawers and seeing how they work out.

Thanks for coming by the Carpentry Way on your travels this fine day in early November, 2012. On to post 6

there is always the possibility that over building is just as hazardous as under building.

ReplyDeleteMatsukaze,

ReplyDeletethanks for the comment.

~C

Chris,

ReplyDeleteI saw a glueless planter recently and started to wonder about joints that are held together with out the use of nails and glue. This post was an excellent read in that context. Look forward to seeing the construction of the drawer.

I am wondering if no-glue, no-nail joints are common in chinese/japanese woodworking and if there are any books on this subject.

Thanks for taking the time to blog about your design process. You are one of the woodworker bloggers that truly inspire me and I am glad to see no pocket hole joinery here :)

PhilM

Phil,

DeleteI appreciate your comment. I'll try to hold off on the pocket-hole joinery for as long as i can.

Fully demountable construction was quite common in classic Chinese furniture. When people moved, a cabinet could have its doors quickly removed and the major frame joints knocked apart with a mallet, allowing the entire piece to disassemble into a tidy bundle of panels. Chinese traditional furniture practice is characterized by a minimum reliance upon glue, and even using too many pegs was frowned upon. Friction fit joinery was the approach. Lathe work on furniture parts was also a no-no.

Japanese furniture doesn't tend to use demountable construction so much, from what I have seen at least. A lot of Japanese furniture pieces were made with quite light structural members, so if the piece of furniture had to be moved, it could be fairly readily carried. Many chests have pole hooks built in on both ends as well.

In both traditional Japanese and Chinese furniture construction, when glue was used, it was of a type which could be reversed. The Chinese liked fish-based glues, and even used lacquer as a mild adhesive, while Japanese practice was to use rice paste- or rice flour-based glues. Nowadays, a lot of Japanese furniture is assembled with 'bondo' a type of aliphatic resin glue (white wood glue), which is not especially reversible. And modern Chinese furniture? Well, let's not go there.

There are no books I've seen specifically dealing with demountable furniture construction, though most of the better books on traditional Chinese and Japanese furniture include a section on joinery methods. Joinery is a very well-developed aspect of either tradition, and no one book really covers the matter in depth.

~C

Hi Chris,

DeleteThanks a bunch for your reply. As always, I learned a lot from it.

I think it is quite difficult to find literature in foreign languages, google translate notwithstanding. Do you have any recommendations for good chinese/japanese woodworking books? I have the books by Seike, Sato and Odate but not aware of any books by Chinese authors on traditional woodworking.

Thanks,

PhilM

Phil,

ReplyDeleteI'm not aware of such books either, though I imagine there might be something out there in Chinese. I mainly look at books on Chinese classic furniture, some of which describe joinery and materials, but not methods of work. I appreciate the conversation with you.

~Chris

Great design!! Simple but coplex!! Have you ever heard of lyptus as a hard durable wood? How does it compare to the green super wood??

ReplyDeleteJ.T.,

DeleteLyptus is a genetically modified plant, and I'm not especially interested in working with it. I haven't seen it at any of the local lumber yards, though I did see some in B.C once. Not my cup of tea.

Thanks for your comment!

~C