Anyone get the reference to the post title from the above picture? You'd have to be over 40 to have a chance I would think - pretty obscure.

The three phase motor I ordered from Hitachi Japan to replace the gear reduced single phase motor which comes with my Hitachi CB-75F bandsaw is not going to be making its way to my mailbox anytime soon. My Japanese hardware store contact, an old friend from Hokkaido named Hayase-san, made the mistake of actually speaking with someone at Hitachi about my motor swappin' plans and, when they learned the motor was going to be exported to the US, declined to sell the motor. Is this anti-US sentiment raising its head once again? No, it's much more mundane than that - Hitachi is wary of any lawsuits that might arise out of using a motor not specifically designed to run on 208v. 3-phase current. The fact that a 200v. motor would probably run just fine, at least fine enough for me to 'risk' it, is not germane to this matter. The Hitachi 3-phase motor is unobtanium from Hitachi Japan unless one resorts to subterfuge.

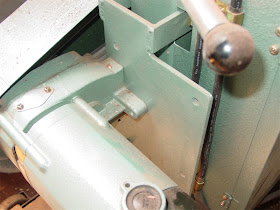

So, I took a look at the mounting plate for the current 110v motor:

As you can see it is a piece of 5mm plate with the motor bolted onto just a portion of the plate. I remembered from the parts diagram for this machine that the mounting plate is the same for both models and it is obvious the mounting plate has ready provision to mount either motor. The question is this: is the provided mounting pattern something unique to Hitachi, or is is a standardized pattern that other motors will fit? Of course, it is possible to adapt a motor to the plate regardless, either by drilling new holes or bolting a secondary mounting plate into position, but I was looking to see if there was a relatively simple 1-banana bolt-on solution which didn't require fabrication or modification to the machine.

I put a ruler on the bolt spacing to check - the width is 125mm between holes:

And the length the other way is 140mm:

These numbers seemed rather convenient. Nice and round. I also measured the output spindle of the gear drive and it measured 24mm. I did a bit of research and discovered that this combination of dimensions spells out a standard metric size of electric motor frame - the 'D90L' in this case. There are two versions of motors for the D90L frame, one turning around 1800rpm and the other something like 3450rpm. Given the size of the pulleys for the belts, with the pulley at the bandsaw's lower wheel being about twice as large as the pulley on the output drive end, and the target bandsaw wheel rpm of 900, it follows that the 1800rpm motor should be a more or less perfect fit. That motor is about 2h.p, or 1.5kw, and by miraculous coincidence the Hitachi 3-phase motor for this machine is also 1.5kw. Baldor and Leeson both make motors in the 1800rpm variety and there are many to choose from on the market, new, NOS, used, rebuilt, etc., so I'll be picking one up soon. Along with the new motor, I'll obtain a couple of longer belts and the specific belt cover from Japan (if the gods are willing). I'll also look into whether link belts will fit the drive pulleys.

I also obtained a Hitachi 6mm bandsaw blade, and fitted that onto the machine. The Hitachi guides were a bit fiddly to set up and are configured so that the bandsaw blade sits further inboard on the wheel tires than is suggested in the manual, but that's the only way it would work. The lower guide seems to have a mounting shaft which is slightly short and this means the blade has to be positioned further inward to meet it properly. It is what it is I guess. Here's the upper guide now set up:

Once I've run a bit of wood through it I'll know more about how well this all works.

I've also been on the hunt for a sliding chopsaw. Ideally, I'd like to get a large German made Graule ZS200N saw like this:

This company has no representation in North America, however I did see and use one of these on Vancouver island so the odd one has made it's way over. They're expensive. They're awesome. Maybe some day - some day when I have 460v service!

I considered a Northfield Unipoint saw:

In the end, I decided, in terms of resource allocation, that a consumer grade sliding compound chopsaw would do the job for the time being and would be something portable to take to job sites when required. And they are a whole lot cheaper than the industrial quality machines of course. I looked at Festool, Makita, Hitachi, Ridgid, Bosch, and Dewalt, weighed the apparent pros and cons, realized each of them would have both their good points and idiosyncrasies and flaws, and in the end chose the newish Dewalt DWS780 12" machine. I liked its relative simplicity (compared to the Bosch anyhow), large 19" crosscut capacity and the shadow light system looked intriguing. It was also $200 less than the Bosch and that sealed the deal. Here it is, looking for a home in my shop:

The white light around the bottom of the blade is what you get with the shadow light system turned on. it both illuminates the cut area and provides a cut line.

Another view:

I suspect that the blade that comes with this machine, like Dewalt blades in general, isn't the best, so I'll keep it for use cutting rougher material, and have ordered an 80T Forrest Chopmaster to be the main blade for use. I'll be mounting this up in a stand soon enough in my shop.

I was also looking for a tablesaw. My dream machine is out of reach for the time being, so I was considering a variety of options. One machine to which I gave a really close look, following the recommendation of an acquaintance, was this Tannewitz XJSW saw, built in 1961:

This saw has a sliding table (the 'S' in the model name XJSW), plus extension table (the 'W') and can accommodate up to a 20" sawblade. It weighs 1950 pounds.

The saw has a beautiful scraped ('flaked') top, and two different types of rip fences:

Unlike most older Tannewitz's, this saw had almost all the accessory miter gauges, sectors, and so forth - even a factory brochure and machine blueprint:

I very nearly bought the saw, but in the end decided against it for a variety of reasons. I may change my mind on that, but I'll continue the search in the meantime.

I'm not going to be in the shop much this week as we have just finished moving house and have a mountain of boxes to sort through, and my truck has decided to call in sick with a rear wheel bearing issue. I've ordered the new bearings and seals for the repair and should have it back on the road by the end of the week. Fingers are crossed.

All for now, over and out. Your comment is always welcome.

Don't put me in that age group yet....35 and I got that reference. :)

ReplyDeleteChris,

ReplyDeletewell, it is a matter of time until you cross that line. Glad you got the reference!

Dale,

good to hear from you and glad you enjoyed the update. I am sure many readers would like something along the lines of a build thread or hand tool focused post, but right now it's machinery that is in play for me. Thanks for hanging in there!

~Chris

I'm really jealous of the wide variety of tools you have access to down there. It's not fun trying to get good power tools here in Nova Scotia. Just a couple of rusty Generals and a sea of terrible Rockwell Beavers. The Northfield stuff is awesome, too bad I'll never afford it.

ReplyDeleteAdam,

ReplyDeleteI imagine it would be difficult in Nova Scotia, however there are benefits to living there otherwise, hmm?

I was looking at an online auction recently for a closed furniture plant in Ontario, and noticed that the average sales prices for different pieces of equipment seemed rather high. I suspect the reason might be the market is a little different in Canada. The border, and the delight taken by Canada Customs Services to slap duties and taxes on anything they can makes importing a machine from the US, especially factoring in the trucking costs, a prohibitive proposition I suspect.

I imagine the range of machines in the greater Toronto area might be decent and thus that would be the place to look for a guy stuck out in the forbidding wilds of Nova Scotia - what say you?

~C

I could probably send you a motor if the solutions you are looking at don't pan out.

ReplyDeleteHi Dennis,

ReplyDeletethanks for your generous offer to help. You know, the price on the motor in Japan is actually pretty good, but with the strong Yen and high shipping costs due to them motor weight it ends up costing more than a US-produced motor. Still, I appreciate your willingness to help out!

~C

I am just now doing the same with my CB75F. I took off that nasty noisy piece of shit motor and checked out the plate. It already has holes drilled for a standard 145T frame motor. I will mount a 3HP 3 phase motor with a VFD to vary the speed. I wonder if anyone else has done this? Thanks...Bob Pulver

ReplyDeleteHi Bob,

ReplyDeletethanks for your comment. A 145T motor frame? I just looked up the specs on that and it has a 7/8" output, not 24mm. The mounting of the 145T is pretty close, 5"x5.5", and there is a 2hp version turning 1800 rpm so no VFD would be required.

Still, the Hitachi mounting, which was surely designed for a metric frame motor, is simplest using the metric D90L frame, and if you bought an older Baldor EM3558 instead of the newer more efficient EMM3558 it would be about the same price as the 145T without having to do any any messing with the output shaft or motor pulley. Seems like the more straightforward way to go....

~C

I am doing it this way on purpose as I want variable speed. I have 3 phase in the shop but will use a single phase to 3 phase VFD So it will be easy to move around.

DeleteThe shaft size was not an issue as I would get whatever sheave I need to make it line up. I will use a 3HP 1800 RPM motor as the saw can use all the help it can get in the power department. I am using the 3" blade also so that makes a big difference. One nice aspect of the VFD is I can speed up the motor way past the 1800RPM and it has a braking option that I like. I have a 42" Tannewitz and believe in brakes! I put a 20HP VFD with hard braking on the Tany and got rid of the huge direct drive 7HP motor that was the original. Chris, there is barely a mm difference in any of the mounting dimensions between the 90L and 145T so it did not matter to me. The 145T motor size is very easy to find. Thanks for your comment, I figured my note would just go into the wind.

Bob,

ReplyDeletegood to hear from you again, and thanks for the explanation. Let me know how it works out when you are done with the conversion.

~C